Checking Compression

By David Poche

There are two simple tests of engine compression that will separate good running outboards from worn machines. The results of these tests may be the deciding factor of purchase or non-purchase of an outboard. In the long term, it might also save money and repair time for the new owner. One should check the specifics for each prospective model since there is some variation in design and production, and therefore different ideal compression reading.

Most small horsepower (up to 25 hp) two-cycle outboards built prior to the 1960s had a compression ratio of about 6 to 1. So 6:1 comp ratio and 88 psi is a good and valid value for MANY or even most low horsepower models but there are exceptions and variations to every general rule. This compression ratio means that the outboard is designed to compress the fuel/air mixture at 6 times atmospheric pressure. Assuming atmospheric pressure of 14.7 psi (pounds per square inch at sea level) then the pressure in the cylinder should reach 6 times 14.7 or about 88.2 psi. Since most of us do not live at sea level, the actual ideal theoretical cylinder pressure should be slightly less than that since the atmospheric press is less at higher elevations.

Good working outboards generally have a compression of 75 to 85 psi. Any readings below 70 psi are considered to be low compression.

What Causes Low Compression?

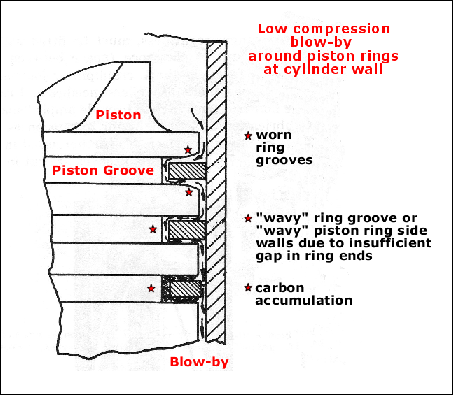

Besides obvious things like blown head gaskets, etc., the next most common thing contributing to low compression in an outboard is leaking or misfit due to wear of the piston rings and cylinder walls.

In order to have good compression, piston rings must be free (in the piston ring groove) to expand against the cylinder walls of the outboard. Any tightness or binding of the ring against the wall will restrict the normal expansion activity of the ring and will result in loss of compression and outboard power. Seepage or escape of compression by way of the piston rings is often referred to as "blow-by".

Piston rings can bind or seize up in the piston grooves either by carbon accumulation or insufficient piston groove or or ring gap clearance. This will cause loss of power, hard starting and unsatisfactory slow speed performance due to loss of compression.

Operating speed of the outboard is most affected at low rpm because slow compression loss around the piston rings is easier than at high speed. Detonations at the top of the cylinder are coming faster than blow-by compression loss around the rings can occur.

Types of low compression blow-by around piston rings.

Testing Compression using the "leakdown" or "bounce" method

To perform a compression test without a compression gauge, turn the outboard over by hand (utilizing its recoil start at normal starting pull speed), and gauge the amount of bounce you feel as each piston passes top dead center (TDC) position of its stroke.

In a healthy engine, the bounce should be readily detectable. At high compression, there should be some resistance and there is a tendency for the starter handle to recoil back as TCD is reached. Compression will usually be low if the engine bounce is weak as its pistons pass the TDC position; it just sort of oozes by the TDC position.

This test is pretty subjective and not very repeatable but it is a simple compression test that one can use at the time of purchase. This test should be performed when the outboard is cold and dry of oil or additives.

Testing Compression Using a Pressure Gage

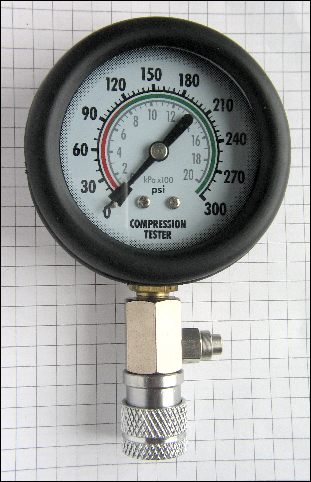

Perhaps a better repeatable test for compression involves using a compression gage. Inexpensive compression gage testing kits are available from tool warehouses and auto supply stores. The kit like the one shown below consists of a compression gage and several fittings for adapting the pressure gage to the individual outboard spark plug hole.

Testing of each of the cylinders of the outboard requires that the outboard be cold and dry meaning that the outboard should not have been run prior to the test and that no oil or other additive be added to the cylinder prior to the test.

A cylinder compression tester with several adapters for fitting the gage to the spark plug hole. The kit shown is for testing of automobile compression. A pressure release valve is shown near the base of the gage.

- Turn off the fuel valve or make sure fuel is not present in the cylinder.

- Disconnect one spark plug wire from the spark plug at a time. Don't mixup the spark plug wires. Be sure to ground the spark wire when testing the compression. Cranking the motor with the plug wire hanging free can ruin the coil.

- Screw in the tester with the appropriate adapter into the spark plug hole.

- Crank the motor over with the pull start about 4 to 8 times at normal starting speed. Watch for a stabilized peak pressure on the gage. This is the compression value for the cylinder.

- Release the pressure on the gage.

- Repeat to other cylinders.

Each cylinder should read within 3 to 5 pounds of each other. Any pressure below 70 psi would be considered a low compression outboard.

Will it run with poor compression?

Poor compression in an outboard results from cylinder pressure leakage usually around the cylinder rings. As the outboard "ages", the cylinders become out of round from wear and this allows pressure leakage around the ring gap. Poor compression numbers might also mean that there is hidden wear to the engine at the crank or bushings as well as the cylinders. To help premature wear, proper fuel/oil ratios should always be used.

Author's Note: Thanks to Lloyd Lautner, Senior Member of the AMOCI, for lending his expertise to the author on this project.

Some Video Examples of Compression Testing:

http://www.youtube.com/watch?v=PyCw4SiuT2I&feature=channel

Notice: that the person in this video first uses a quick "bounce" test and confirms low compression then confirms the bounce test with a gage compression test in each cylinder. This is a good video showing both tests.

http://www.youtube.com/watch?v=lAyrgOF9QxY&feature=channel

Notice: Yes, he did get it running but outboard still has low compression as it does not run well at idle speeds. This can be confirmed in the video since he is able to adjust the engine speed downward to the upper end (fastest) of the "slow" speed position before the engine dies. The engine does not idle properly because of low compression.